“We were the first in the world to make hydrogen from outdoor air and sunlight”

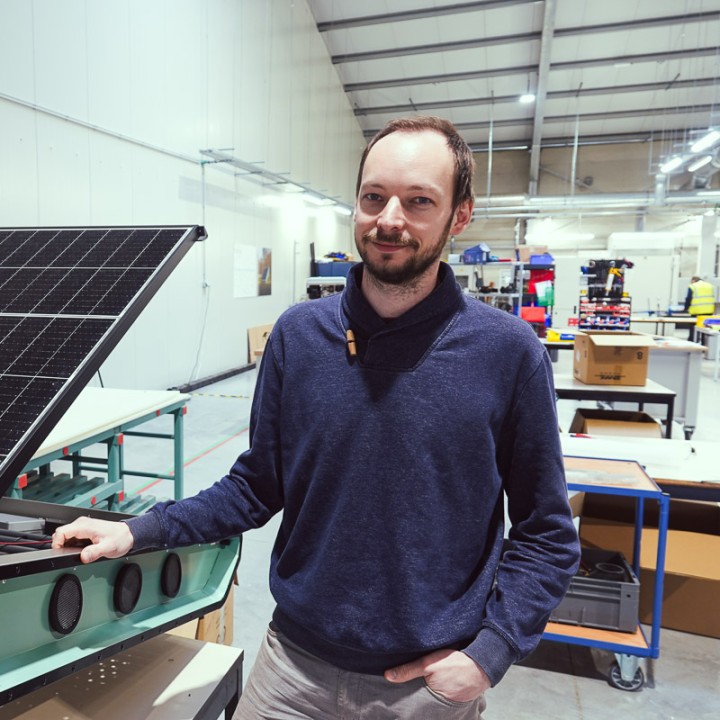

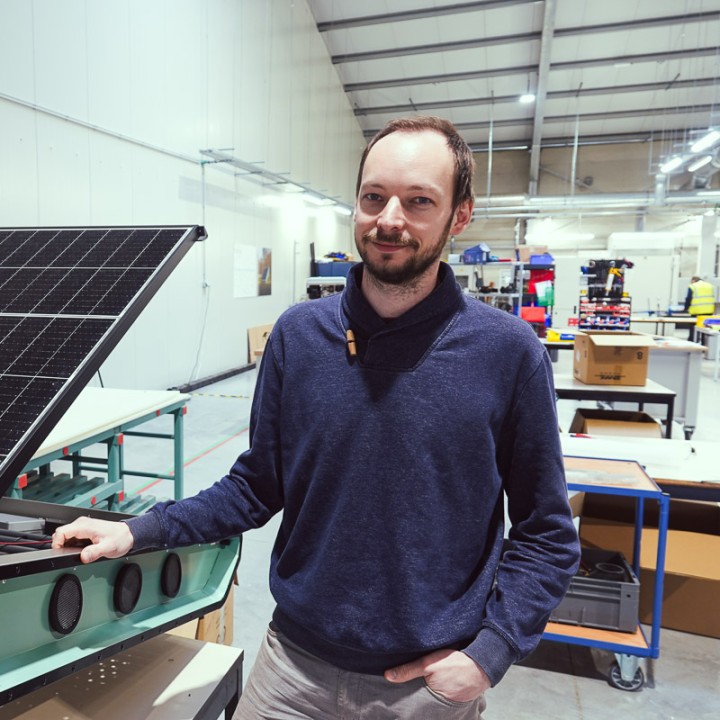

The Later Stage Innovation (LSI) project HyPPr ended in mid-2023. This Moonshot project in Energy Innovation was followed by the technology startup Solhyd, which seeks social impact with a widely deployable hydrogen panel. Hydrogen gas will play an important role as an energy carrier of renewable energy. A pilot production line is currently being developed in which these panels will be further scaled up. CEO Jan Rongé explains Moonshot's importance in the journey and talks about the challenges today.

How did the Moonshot project HyPPr come about?

Jan Rongé: “More than a decade ago, we started from a white sheet to find the best way to make hydrogen using solar energy. That was really a moonshot: working long-term on a technology that could be a breakthrough. Green hydrogen was not at all as well known as it is today. Solar and wind were still viewed with a lot of skepticism. In that context, we started using solar energy to make green hydrogen.”

There was a scientific basis for it?

Jan Rongé: “The idea of making hydrogen using solar energy had been explored since the 1970s, following the oil crisis. Then, on the one hand, research into solar panels grew rapidly, and on the other, research into hydrogen technology powered by solar energy. Decades of research yielded much, but never a product. Yet that was the dream we were working toward. In 2012-2014, we did not want to spend another forty years in the laboratory. There was urgency. We said: we need a solution to the climate problem now. We now want a product that converts sunlight and water from the air into hydrogen.”

How unique is what Solhyd does?

Jan Rongé: “Making hydrogen gas directly via solar energy is technologically less obvious than combining electrolysers with wind energy. We make hydrogen from sunlight and the air in the atmosphere. The hydrogen literally falls from the sky. Golden hydrogen we call this. Existing and green hydrogen technology with electrolysers uses electricity and water to make hydrogen. We make hydrogen without power and without additional water. So, our environmental impact is significantly smaller. We produce a completely renewable energy technology because we are independent of external green energy production.”

Becoming product developers

From the start your goal was to make a product?

Jan Rongé: “At the time, I did a master's thesis and a doctorate with co-founder Tom Bosserez on the topic. This started with basic academic materials research, which was very useful to know what works and what doesn't, what the fundamental principles are. We learned a lot from that. Pretty soon we saw that the level of humidity in the air matched well with the amount of solar energy that could be converted into hydrogen gas. We saw that we didn't even need liquid water. We could just use air along with light. This was in 2013. From the beginning of our research, we had a panel in mind. With our research, we showed that it could be done. We were the first in the world to make hydrogen from outside air and sunlight.”

On what scale did all this happen?

Jan Rongé: “This was done on a centimeter scale (1 cm2). We were making so little hydrogen that very expensive apparatus was needed to even demonstrate that we were making hydrogen and to quantify the quantities. That was the very first demonstration, but a very big step.”

You were able to move fairly quickly to a spin-off (Solhyd) after the later-stage innovation project within Moonshot?

Jan Rongé: “In the doctoral years, we laid the scientific foundation, selected the materials, and ferreted out the principles. It was quite new. The scientific literature did not talk about extracting hydrogen from air. Our technology is also more than a mere catalyst. It was ultimately about a product that had to be affordable and scalable. In 2017, we began to focus on the product itself.”

The academics became product developers.

Jan Rongé: “That was quite an evolution. We had to reinvent ourselves as product developers and entrepreneurs. In academia, you do things that are interesting and new, often very complex. You gravitate toward things that are difficult to scale. We cut out everything that is not essential to the product and makes it unnecessarily more expensive. In the beginning, we even made our own solar panels in the clean room, then we worked with solar panels custom-made for us, and today with ordinary commercial modules. We were making it too difficult for ourselves. Today we rely on an industry that has scaled up and we take advantage of that market. The essence is to be as efficient and affordable as possible.”

Affordability and scalability

No scarce or expensive materials were used?

Jan Rongé: “Out of principle, but also for affordability. A solar panel should cost nothing and so should our hydrogen panel. A classic electrolyser can be compared to a nuclear power plant. It has to be used very intensively, justifying more expensive materials and a higher price. We follow an opposite strategy: extensive use, directly with sunlight at low power and therefore it should cost all but nothing. That's why we omitted expensive materials. We never resorted to precious metals. Until this day we are succeeding in this.”

How does your product compare to conventional electrolysers?

Jan Rongé: “The question, of course, is where such conventional electrolysers get their energy. If it comes from solar panels, our solution is smarter and takes up less space. A Solhyd panel in Belgium has a yield of 6 kg of hydrogen per year. So you need a lot of panels. But that's not a barrier when you see how solar power is growing.

For example, we are now working on agrivoltaics, combining agriculture with hydrogen production. If you would use a few percent of the available agricultural area for our panels, you make more hydrogen than is made today in the port of Antwerp from natural gas. The potential is there. It is my personal belief that in Belgium we can produce almost all of our own renewable energy. Not only offshore, but also onshore.”

The potential is there. It is my personal belief that in Belgium we can produce almost all of our own renewable energy. Not only offshore, but also onshore.

Is this potential, e.g. for agriculture, sufficiently known?

Jan Rongé: “There are still barriers. With hydrogen panels but also with electrolysers, it is often still very expensive to make hydrogen and get it sold at a good price. Second, the infrastructure is lacking today. Fluxys is working on a hydrogen network across Europe with its partners. Only when such a network exists, can you activate agricultural areas near the network. The adaptation of infrastructure is essential for the whole energy transition.”

Are you looking for other relevant, new applications today?

Jan Rongé: “We have a luxury problem. While electrolyzer producers are looking for large-scale sites, we can place at any scale and anywhere in the world. Not that it's always the best option, but it can be done. Our goal is that all energy can be renewable. Not only can our hydrogen be an energy carrier but also a feedstock for the chemical industry. We want to help fill the huge demand for hydrogen.

In some very large-scale applications, the relevance is clear. In chemistry, steel and aerospace, it makes a lot of sense. That is where the potential lies in the future. Not only for economic valorization, but also for CO2 reduction. We are looking at such sectors effectively to have impact.

For smaller and medium-sized applications, we are looking at increasing the share of renewable energy thanks to our product. Applications that stay with oil and gas because they see no alternative, but for which we can make hydrogen at their scale. Then this becomes interesting.”

On what scale did the Moonshot project take place?

Jan Rongé: “In the last years of our journey, but still within the academic context, we did two important things. We developed a first-generation hydrogen panel that was reliable enough to test, produce and do first small projects with. Moonshot resources were used to research the product. Also, thanks to Moonshot, we set up a pilot production line and developed the a blueprint for efficient production. This is important. Our technology only becomes interesting thanks to series or mass production, as in the solar panel sector: you develop a module that becomes cheap by producing many of them.”

Where are you today with scaling up and what resources are needed to make it happen?

Jan Rongé: “On the one hand making a cheaper and more efficient second-generation product, which is still a big step, and on the other hand scaling up production. With our current pilot production line, we cannot handle large projects. Within a good two years, we want to start up a plant that does enable large-scale series production based on what we learned here.”

The next generation of hydrogen panels

What does the second generation panel aim for?

Jan Rongé: “Our product is good enough for pilot projects but can be made even more efficient and cheaper. Today we achieve an efficiency in solar-to-hydrogen conversion of 15% in the laboratory on a small scale and with the right materials. With a generation 2 panel, we want to move toward that figure with a low-cost mass-produced panel. Important: for the whole chain from solar to hydrogen, with everything included. Because if you look at electrolyser technology, they give an efficiency often just for the device itself, but there are all kinds of other things involved: purifying and cooling water, all kinds of controls, converting the power. So, you have a lot of intermediate steps. We put the whole chain (with a certain grid capacity, grid connection, conversion, control systems) into one simple device that stands on its own and makes it a process.”

What is the goal for the production of the panels?

Jan Rongé: “The goal is to get to tens of thousands of units as soon as possible. This is megawatt scale or the equivalent of about one wind turbine per year. That's still peanuts. Even if we go to gigawatt scale, a few hundred wind turbines a year, that's already huge, but still too little. To compare: in solar panels alone, about 400 gigawatts of capacity is added every year. We have to be very ambitious if we want to play a role of significance in the energy market.”

The Moonshot funding allowed us to take the final step toward something ready for commercialization.

The relevance of Moonshot

Moonshot was an important link for the HyPPr project. What advantages did Moonshot offer?

Jan Rongé: “Moonshot was important. We are developing deep tech, technology that is disruptive, new and carries risk. Especially in Belgium -in the United States it's a different story- it's not obvious to find people with deep pockets. In 2019, we got some media attention with our first panel. We had a proof of concept. We made one panel with a whole lot of effort. We couldn't even make two at that time, nor could we leave them outside for a year. There were still a lot of steps to take.

Moonshot allowed us to go down a path within an academic context, with two advantages: first, to be able to think long-term - with investors, short term often creeps in. The success of our technology was to think long-term to develop it and get it ready. Second, derisking. When we were effectively looking for investors, we were almost at the end of our Moonshot project. They saw: you have a product, you already know how to make it, you have suppliers, a supply chain. That's way more than an academic group with a nice idea. The Moonshot funding allowed us to take the final step towards a technology ready for commercialization.”

Aiming for impact in AfricaBy participating in projects for developing countries, you license the use of your panels. Isn't it a little early to start doing that? Jan Rongé: “Not exactly. Ten years ago, we wanted to develop a technology that has an impact on the world. From 2017-2018, we started thinking explicitly about maximum social impact, given that this product can be decentralized. Today a huge amount of financial aid from organizations such as the World Bank goes to solutions that help people cook 'clean', because cooking with open fires is a major cause of deforestation, three or four million deaths a year, gender inequality, etc. The funding, however, goes to so-called "improved cook stoves," wood-fired or LPG. This is promoted as clean. We believe that hydrogen can be an alternative to this as well. People can use this panel to provide their own hydrogen locally, without depending on suppliers. Often something is commercialized for 10 to 20 years in the West and no thought is given to introducing it for impact applications in the South or only after so much time. We no longer have the time to wait. For this reason, we set up the Solhydair Foundation. A company was created in partnership with COOSHA Impact Venture to set up pilot projects, including in Namibia and Congo. With Solhyd we are also involved in Rwanda and Uganda. It is certainly not too early for that. There is much more sun and humid air over there. Africa is the growth continent. Even purely economically speaking, it would be foolish not to be involved there.” |